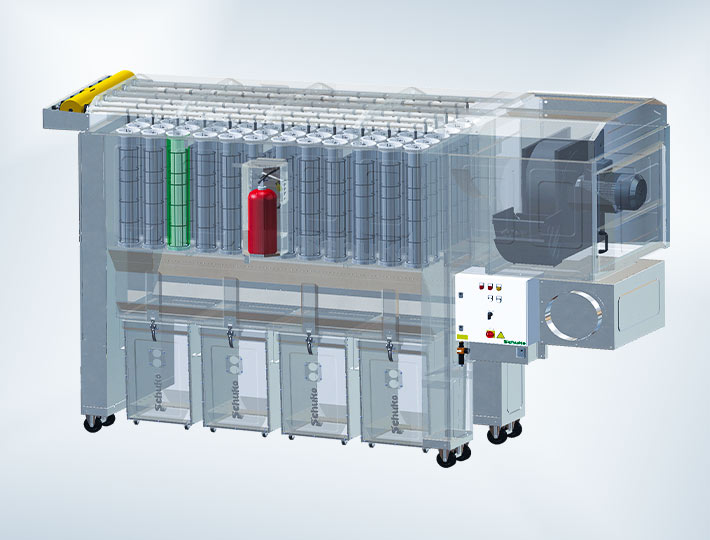

Large dust extractor with four chip collection tanks

- For powerful centralised multi-point extraction

- Highest operational safety due to some technical features (see below)

- Can be combined with various chip discharge systems

- Equipped with proven SchukoCone filter bags

- Delivered preassembled and ready to plug in for immediate use

Questions

on this product?

Description

The Vacomat 350 XP large dust extractor is the ideal filtration system for multi-machine extraction. Airflows of up to 7,950 m³/h are possible with this clean air extraction system, making it interesting for CNC machines, wide belt sanders or complete workshops.

The standard Vacomat 350 XP comes with an automatic controller to ensure that the powerful extraction system is not forgotten or run at no load. If an attached machine is turned on, the dust extractor fan starts automatically, causing extraction to begin immediately.

Cleaning of the filter bags starts automatically once all connected machine tools have been shut off. Our patented filter shake-off process cleans the filter bags by a combined pneumatic and mechanical action. Via connection to a compressed air supply dust and chips are discharged through a shaking action (inlet pressure: 6 bar, air requirements per cleaning cycle: approx. 11 l).

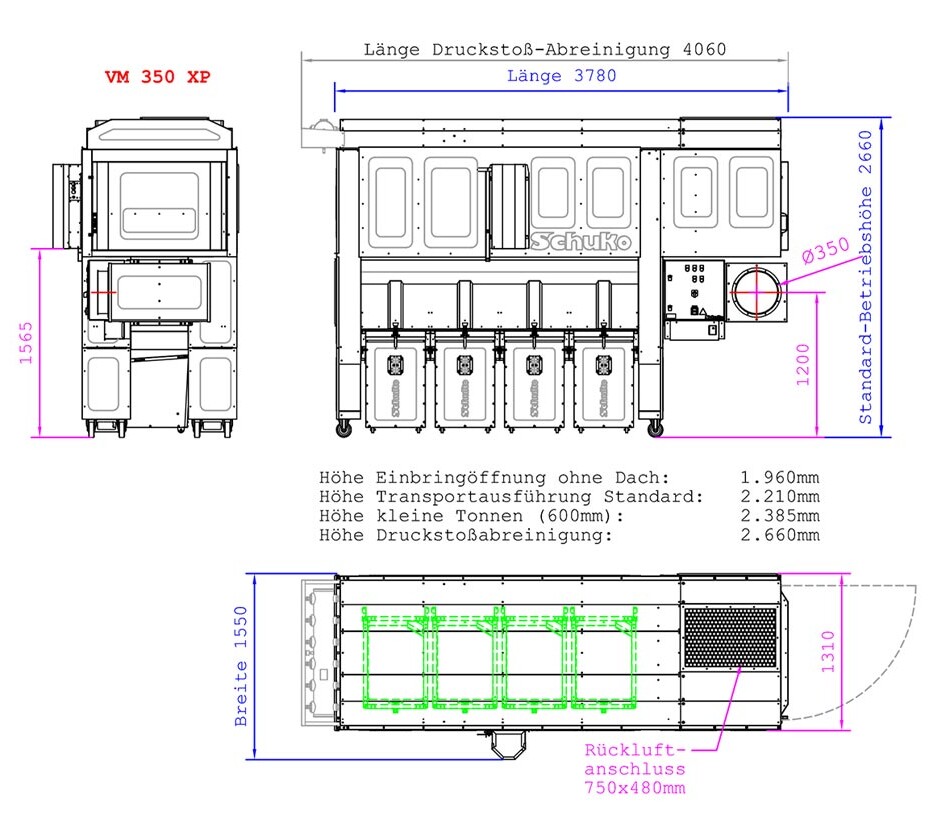

Recommended particularly for very high and very fine dust contents, an efficient pressure surge cleaning system is optionally available (NOTE: overall height then +100 mm and length +350 mm). Cleaning is carried out offline via the compressed air tank after extraction.

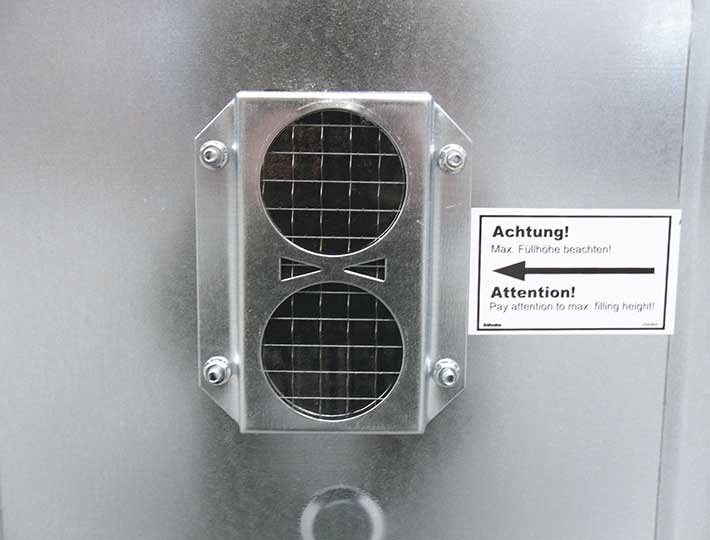

Our Vacomats are modularly constructed. In the standard version the dust and chips are discharged to four dust-tight plastic sack-lined chip collection tanks (4 x 120 l). A negative pressure duct holds the film sacks in place in the collection tank. Inspection windows facilitate level checking.

A level monitor can optionally be installed to prevent overflow of the chip collection tanks. Discharge via chip tanks, ATEX rotary airlock valves and screw conveyors for disposal to a briquetting press, big bags, a container or a chip bunker is also possible.

SchukoCone filters

The Vacomat 350 XP mobile dust extractor comes with patented SchukoCone® filter bags as a standard feature.

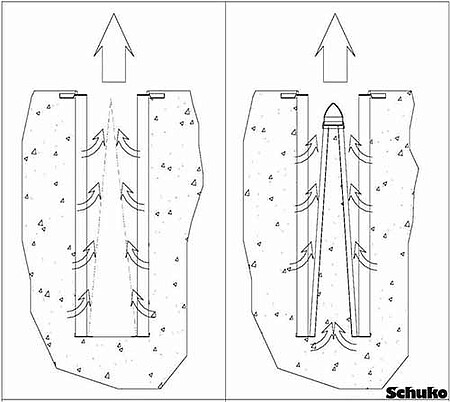

The SchukoCone® filter is a successful combination of an externally loaded filter bag and an internally loaded cone. For today’s system constructions this means approx. 60% more filter surface area with the same length and an up to 50% larger expansion chamber than in traditional dust extraction systems.

SchukoCone® filters should particularly be used for fine dust requiring a high filter surface area and a low filter surface loading rate because it is especially in such applications that the filters realise their tremendous potential.

With a decrease in filter surface loading rate a longer filter life is reached. The filter resistance drops and hence a lower fan output and less power are required.

Other advantages

- Low energy requirements due to modern high-efficiency motor (IE3) ‘made in Germany’ and a flow-optimised housing interior with low air resistance.

- Heat recovery based on air recirculation principle: the hot exhaust air is filtered and returned to the workshop.

- Quiet operation: a double-walled filter bag casing directly absorbs extraction noise generated inside the Vacomat. The fan housing also has a noise-reduced design.

- Approved for indoor installation in wood dust environments – manufactured according to the new DIN standard EN 16770.

- Healthy return air: specially developed high-grade filter materials made from anti-static polyester needle felt filters out 99.9% of the dust and chip waste from the air (dust class M for St1 dust).

- Improved safety through fire and explosion protection measures according to regulation DIN EN 16770: pressure surge-tested to 20,000 Pa, automatically triggered powder fire extinguisher – no water damage!

- Operational reliability: a load cell continuously monitors the extraction performance. Errors are indicated by the signal lamp.

- Low follow-up costs due to high-quality modules and long filter medium life: for example, an extra-large settling chamber provides for initial separation of coarse waste chips. This reduces the material load on the filter bags.

- Low maintenance requirements due to maintenance unit on motor console and easy access to the inside of the filter.

- Modular principle for variety of chip discharge options: o via chip tanks, e.g., to the briquetting press o via rotary airlock valve, e.g., to a big bag o via inclined screw, e.g., to a chip bunker or container.

- Optionally with pressure surge cleaning for especially high and fine dust contents

Installation & items delivered

The Vacomat 350 XP is delivered preassembled and ready to plug in (heavy current 32 A, with 6 m cable). A model-dependent 24 V switchgear cabinet as well as a set of chip collection bags (4 pcs, size V) are also included. The roof can easily be removed for transport (height reduction of 170 mm) to enable smooth passage through doors.

The Vacomat 350 XP must be electronically connected to the machine tools to enable automatic fan start-up and automatic triggering of filter bag regeneration when the machine tools are shut off. An electronics company can help. The supplied switchgear cabinet is prepared for querying of up to eight machine tools.

The dust extractor is directly connected to the tools for extraction (connection nozzle size of 350 mm) with a flexible hose or rigid ductwork. With this performance class it is advisable to have the line routing planned and executed by a specialist. Some of the connection parts can be found in the accessories section as well as our system components section.

Equipped with stable industrial-grade casters, the mobile dust extractor can be set up flexibly anywhere in your workshop. Need extraction for a different machine? Just release the brakes on the two casters and push the unit to the required location.

We would be happy to assist you in the planning!

Technical data

Downloads

Product brochure

brochure mobile dedusters VacomatMobile dust extractors with chip collector for indoor installation are suction units ready to be connected for the extraction of one or more machines.3 MB

brochure mobile dedusters VacomatMobile dust extractors with chip collector for indoor installation are suction units ready to be connected for the extraction of one or more machines.3 MB

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.