Ideal for pressureless loading of chip silos

- High separation efficiencies due to optimised air construction

- Long life due to patented TWISTER baffle plate

- Explosion protection provided by double 90° deflection of airstream

- Safe discharge through ten-vane ATEX rotary airlock

- Packed on two pallets for low transport costs

Questions

on this product?

Description

Cyclones are used in filtration systems to remove particles and other contaminants from the air. They use centrifugal force to separate the particles from the air and are used in industrial plants to improve air quality.

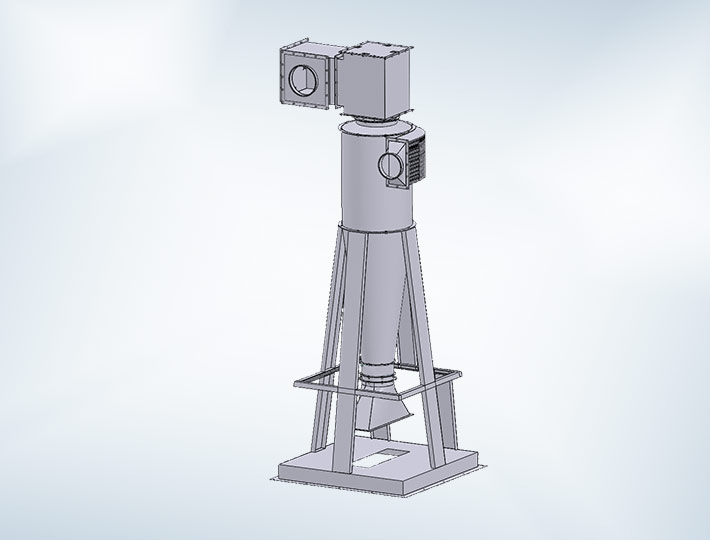

TWISTER type cyclone separators are ideal for feeding chip silos without pressure. Especially for very coarse and lumpy material, a patented Twister impact plate is used in the inlet section of this cyclone separator. This plate cushions impacting solids as they enter the cyclone, thus contributing to enormous wear and noise protection.

This cushions impinging solids entering the cyclone for a considerable reduction in wear and noise.

With a double 90° diversion of the airstream, this construction minimises the risk of explosion. The captured material is discharged pressurelessly and safely to the silo via an operationally reliable and explosion-proof ten-vane ATEX rotary airlock.

The rust-free and weather-proof steel construction made from Sendzimir-galvanised sheet steel is particularly long-lived and resistant.

Additional advantages

- Excellent wear and noise protection in the inlet section through the patented TWISTER baffle plate

- Satisfies requirements of ATEX zone 21 – suitable for silo loading

- Weather-resistant, Sendzimir-galvanised sheet steel construction

- Safe and quick assembly in a few hours due to modular system with simple assembly instructions

- Large high-quality rotary airlock for reliable material discharge even with high volumes of material

- Easy access at inspection or maintenance

Installation & items delivered

The TWISTER cyclone separator is delivered in disassembled condition on two pallets. With the included assembly instructions, it can be assembled within three hours by only two persons and appropriate assembly aids (forklift).

Downloads

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.