For residual wood shredding

- Easy shredding of waste wood and residual wood, MDF, chipboard, pallets and co

- Different screen sizes for the desired final chip dimensions

- Chip briquetting possible

- High throughput at low noise level

- Energy-saving slow running with the latest IE3 motors

- Automatic idle machine shutdown

- Long-lasting, replaceable blades

- Robust, durable construction

Questions

on this product?

Description

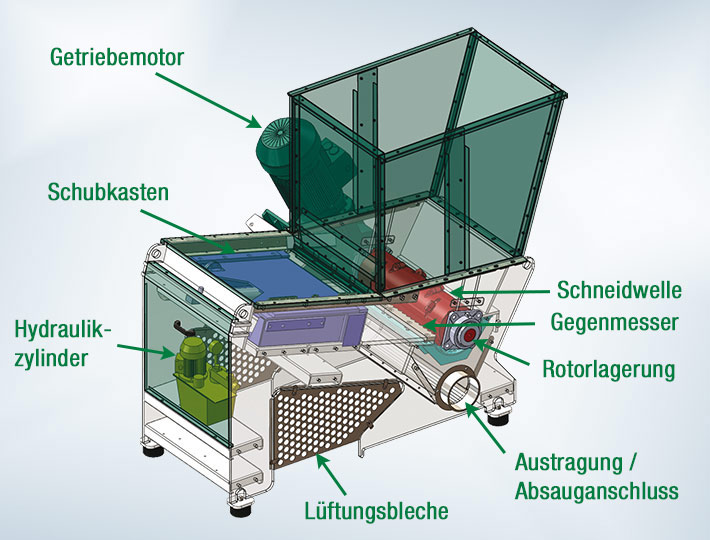

If you need to cut up your waste wood into wood chips, then our single-shaft shredder is right for you. With a powerful cutting shaft each of our three sizes effortlessly cuts up all waste wood, even entire pallets.

The inclined feed-in tray presses the input material against the rotating cutting rotor. A screen underneath with a mesh size of 14–30 mm retains large pieces in the hopper for further comminution. The differently sized screens can easily be changed according to the further processing requirements for the shredded product.

The cut-up wood can, for example, be used for in-house heating or compacted in a briquetting press as required. Residual metal parts such as nails are segregated via an in-line magnetic separator.

An extraction system or an inclined screw discharge system for direct conveyance, e.g., to a chip bin can be installed for automatic disposal of the shredded product.

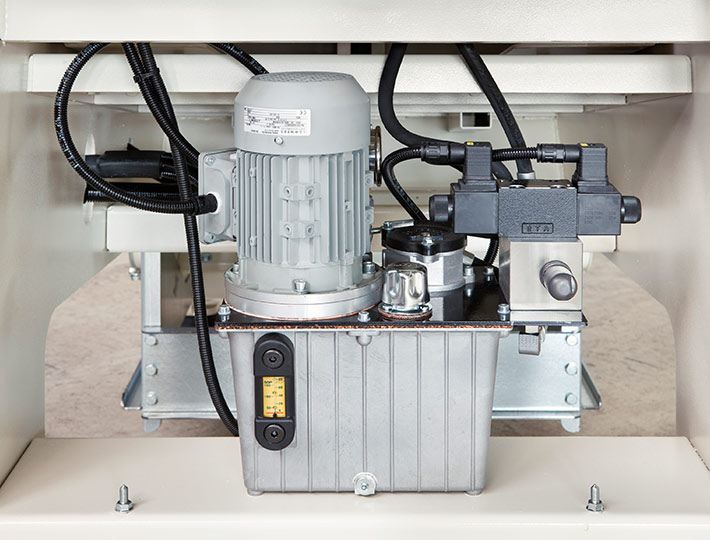

A money-saving high-efficiency motor (IE3) is used for the gear drive. Owing to the direct drive, our shredders output approximately 10% more power at the shaft than belt-driven models and thus operate much more effectively. To save additional power all Schuko shredders shut down automatically when idle.

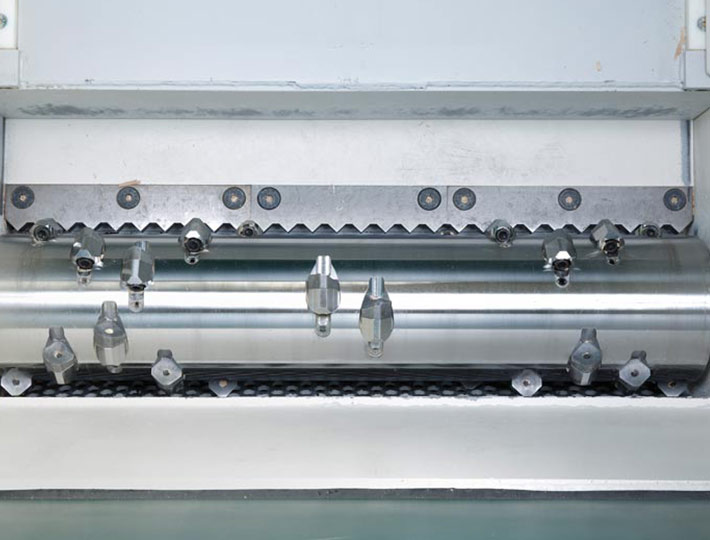

Schuko shredders are distinguished by their long life and trouble-free operation. They feature solid constructions with low-wear all-steel cutting shafts. The material feed-in tray is inclined for a higher material throughput. This causes the input material to be pressed against the cutting shaft with a higher force. Double-sided break-proof blades and easy-to-reach lubrication points minimise follow-up costs and maintenance requirements.

Schuko attaches great importance to system safety according to applicable standards. All shredders bear the CE mark.

Other advantages

Robust, strong, long-lived and economical

- Solid 15mm flat steel construction for a long service life.

- The ZM 1000-K size has additional reinforcements on the motor mount and torque arm.

- Low-wear pusher guide with highly wear-resistant polyamide (PA6).

- High material throughput through inclined construction causing the input material to be pressed effectively against the solid all-steel cutting shaft.

- Schuko blades with clearance and cutting angles ensuring optimal cutting results. They generate savings of up to 2 kW in motor power, can be turned for dual use and can be individually replaced at any time.

- Side rakers prevent material wrapping around the end of the rotor shaft.

- Counter-blades that can be turned for dual use.

- Individually adjustable chip sizes through exchangeable screens with different mesh sizes.

- Direct-drive motor for higher shaft output, low maintenance and no belt retightening.

- With high-speed heavy-duty gearbox to drive the rotor shaft. Belt slip is eliminated and wear is minimised.

- Smooth-running drive unit (motor and gearbox) for a long service life.

- Motor-protecting and disturbance-free shredding thanks to electronic monitoring of power consumption and reversal of direction of rotor shaft rotation in overload situation.

- Maintenance-friendly hydraulic unit with oil level indicator.

- Space-saving switchgear cabinet, suitable for external wall mounting, with user-friendly PLC for continuous adjustment of machine running time, operating hours indication, text display in fault situations and activation of the energy-saving idle shutdown mode.

Installation & delivery

technical Data

| Modell |

ZM 800-K |

ZM 900-K |

ZM 1000-K |

ZM 1300-K |

|---|---|---|---|---|

| Art. no. | 975 300 | 975 400 | 975 500 | 975 600 |

| Material performance kg/h | 220-300 | 250-350 | 300-700 | 400-900 |

| Funnel opening D+E mm | 710x990 | 710x990 | 990x990 | 1,270x990 |

| Funnel capacity m³ | 0.5 | 0.5 | 0.7 | 0.9 |

| Rotor Ø mm | 220 | 220 | 220 | 220 |

| Length of rotor mm | 680 | 680 | 960 | 1,240 |

| Rotor speed U/min | 115 | 114 | 114 | 114 |

| Motor power kW | 15 | 18.5 | 18.5 | 18.5 |

| Cutter/pc | 19 | 19 | 27 | 35 |

| Rakers | 2 | 2 | 2 | 2 |

| Hydraulic feed | yes | yes | yes | yes |

| Extraction port Ø mm | 180 | 180 | 250 | 250 |

| Air rate (m/s) required | 28 | 28 | 32 | 32 |

| Machine resistance Pa. | 450 | 450 | 430 | 430 |

| Weight kg | 1,400 | 1,450 | 1,700 | 2,100 |

| Length A mm | 2,050 | 2,050 | 2,050 | 2,050 |

| Width B mm | 1,270 | 1,220 | 1,800 | 2,150 |

| Height C mm | 1,710 | 1,710 | 1,710 | 1,720 |

The standard screen perforation corresponds to 18 mm.

Furthermore, sieve sizes in 14, 24 and 30 mm are available.

![[Translate to Englisch:] technische Zeichnung Zerkleinerungsmaschine Seitenansicht [Translate to Englisch:] technische Zeichnung Zerkleinerungsmaschine Seitenansicht](/fileadmin/_processed_/1/6/csm_technische-Zeichnung-Zerkleinerungsmaschinen-Seitenansicht_a9bf185a65.jpg)

![[Translate to Englisch:] technische Zeichnung Zerkleinerungsmaschine Draufsicht [Translate to Englisch:] technische Zeichnung Zerkleinerungsmaschine Draufsicht](/fileadmin/_processed_/b/e/csm_technische-Zeichnung-Zerkleinerungsmaschinen-Draufsicht_103fce3a4a.jpg)

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.