Central extraction systems for indoor and outdoor installation

- space-saving compact design for indoor or outdoor installation

- Tested filter material for healthy return air (residual dust content <0.1 mg/m³)

- high quality thanks to the design in accordance with EN 16770 or EN 12779

- high level of safety due to pressure shock resistant housing up to 200 mbar (according to dust explosion class St1)

- Modular principle for individual component composition

Questions

on this product?

Description

Stationary dust extractors of the type Vacomat N-1000 and N-1800 close the gap between mobile dust extractors and industrial filtration systems. The technical diversity is of interest both for small to medium-sized enterprises, as well as for the large-scale industry, e.g. as a supplement to the central extraction system.

The Vacomat combines the advantages of large industrial filtration systems in a compact, flexible and highly efficient centralized dust extractor. The essential distinguishing feature compared with similar devices lies in the design:

1. Our stationary Vacomat can be operated at a flow rate of max. 8,000 m³/h. Equipped with an automatic powder extinguisher (in accordance with EN 16770), the dust extractor is approved for installation indoors as well as outdoors.

2. With a dry extinguishing line and pressure relief surfaces (according to EN 12779), the dust extractor becomes a small filtration system for air volumes of up to 8,000 m³/h.

As a filtration system, the Vacomat may only be installed outdoors.

Thanks to an intelligent modular system, a wide variety of variations are available as standard, which are otherwise only produced in expensive special designs:

- adaptation of the fan power to the required extraction requirement, among other, through a twin fan concept

- design as vacuum or excess pressure system (only as filter)

- individual composition of the chip discharge and the disposal system

- demand-based attachment of the extraction nozzle

- determination of the ideal location indoors or outdoors as well as equipment according to the associated safety regulations for indoor or outdoor installation

- energy-saving return air operation also possible for outdoor installation

Chip discharge

Bagging unit for two chips collector barrels for disposal via chip collection bags

Chip container with stirring sickle and screw discharge, for disposal with briquetting press, BigBag or Container

Chip container with stirring sickle and discharge via ATEX rotary valve, for disposal with briquetting press, BigBag or container

Substructure with discharge into large ATEX rotary valves, for disposal in BigBag or Container

Other advantages

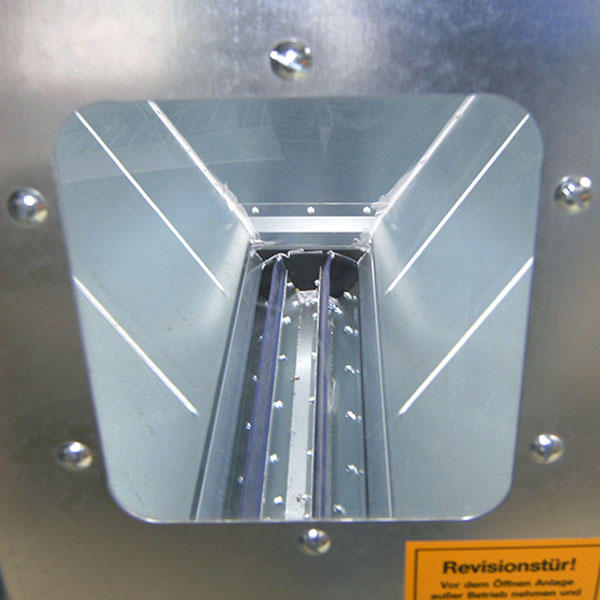

- Filter-friendly and quiet material entry through chip blow-in box with backflow flap and additional sound insulation.

- High security through automatic fire extinguisher with powder extinguisher.

- Tested safety and quality, manufactured according to EN 16770 or 12779.

- Shock resistant housing up to 200 mbar.

- Constant self-checking of the existing extraction performance at the extraction nozzle of the connected machines via volume flow monitoring.

- Clean and healthy return air due to certified filter material (residual dust content <0.1 mg/m³).

- Long service life of the filter tubes due to high-quality, antistatic polyester needle felt material and large expansion area (blow-in space), through which a first separation of coarse, heavy material takes place, which does not load the filter tubes additionally.

- For more filtration area with the same space requirement with SchukoCone filtration tubes.

- For industrial special applications, e.g. plaster dust, glass dust, B1 dusts, available with filtration cartridges (filtration areas from 210 to 270 m²).

- Continuous operation possible through the use of our efficient pressure surge cleaning (standard with the use of filtration cartridges!).

- Maximum housing durability thanks to sendzimir galvanized steel sheets, which optimally protect against wind and weather influences (stronger galvanizing than in cars).

- Quiet operation thanks to soundproof fans between 70 - 76 dB (A) - comparable to a lawnmower.

- Individual chip discharge and disposal through various filter substructures in stable, self-supporting steel construction, which can also be subsequently replaced if required.

- Customer-oriented PLC control for energy-saving and user-friendly operation.

- Fastest installation and commissioning thanks to pre-assembled elements, which are assembled in a modular manner.

- Optionally with automatic fan start when switching on a connected machine.

- Optionally with automatic filter regeneration, which starts automatically as soon as all connected machines are switched off.

Installation and scope of delivery

Thanks to the Schuko modular system for filtration systems, the installation of these small filtration systems is as quick and easy as never before. With the time-saving pre-assembly of individual components in our Schuko plant, the finished elements only have to be assembled on site.

Such a filtration system can usually be set up with two technicians on one day (only assembly time!). In the standard height only a forklift is needed.

For installation on a base frame, a crane is required.

The scope of delivery includes the control with pressure cell and signal light for monitoring the flow rate, a pressure gauge with water separator of the compressed air and the control of the filter regeneration.

Attention: Depending on the equipment, an additional switch cabinet is necessary.

Technical data N-1000

Filter unit with three different filter systems

| Type | Art. no. | Filtration surface area | Filtration medium, length | Dimensions L x W x H | Filter regeneration | Compressed air requirement per cycle | Weight |

|---|---|---|---|---|---|---|---|

| N-1000 10/25 | 633 150 | 25 m² | Tube, 1,000 mm | 1,520 x 1,520 x 1,760 mm | pneumatic/mechanical,optional pressure surge | P max 6 bar, 40 l / 4 bar | 360 kg |

| N-1000 15/37 | 633 250 | 37 m² | Tube, 1,500 mm | 1,520 x 1,520 x 2,260 mm | pneumatic/mechanical, optional pressure surge | P max 6 bar, 40 l / 4 bar | 580 kg |

| N-1000 20/50 | 633 350 | 50 m² | Tube, 2,000 mm | 1,520 x 1,520 x 2,760 mm | pneumatic/mechanical, optional pressure surge | P max 6 bar, 40 l / 4 bar | 380 kg |

| N-1000 25/62 | 633 360 | 62 m² | Tube, 2,500 mm | 1,520 x 1,520 x 3,230 | pneumatic/mechanical, optional pressure surge | P max 6 bar, 40 l / 4 bar | 420 kg |

| N-1000 1.25/50 | 633 850 | 50 m² | SchukoCone, 1,250 mm | 1,520 x 1,520 x 2,000 mm | pneumatic/mechanical, optional pressure surge | P max 6 bar, 40 l / 4 bar | 425 kg |

| N-1000 10/210 | 633 750 | 210 m² | Cartridge, 1,000 mm | 1,520 x 1,520 x 2,070 mm | pressure surge cleaning | P max 6 bar, 182 l / 4 bar | 387 kg |

| N-1000 10/270 | 633 450 | 270 m² | Cartridge, 1,000 mm | 1,520 x 1,520 x 2,070 mm | pressure surge cleaning | P max 6 bar, 182 l / 4 bar | 425 kg |

Ventilatoreneinheit

| Typ | Art.-Nr. | Motor-leistung | L x B x H (mm) | Schalldruck-pegel | Nennvolumen-strom | zugehöriger Unterdruck | Gewicht mit Rückluftbogen |

|---|---|---|---|---|---|---|---|

| VacoVent 400 | 826 100 | 4,0 kW | 1.230 x 840 x 905 | 70 dB(A) | 3.416 m³/h | 3.136 Pa | 141 kg |

| VacoVent 550 | 826 200 | 5,5 kW | 1.230 x 840 x 905 | 71 dB(A) | 5.315 m³/h | 3.365 Pa | 150 kg |

| VacoVent 750 | 826 300 | 7,5 kW | 1.230 x 840 x 905 | 72 dB(A) | 6.180 m³/h | 3.440 Pa | 155 kg |

| VacoVent 1100 | 826 400 | 11,0 kW | 1.230 x 1.000 x 905 | 76 dB(A) | 7.697 m³/h | 3.875 Pa | 176 kg |

technical data N-1800

Ventilator unit

| type | art. no. | power consumption kW | dimensions L x W x H (mm) | nominal air volume in m³/h | nominal negative pressure Pa | max. air volumen m³/h | negativ pressure PA at max. air volume | noise level dB(A) | weight kg |

|---|---|---|---|---|---|---|---|---|---|

| VacoVent 2 x 5.5 kW | 826 500 | 11 | 1,260 x 1,300 x 2,500 | 7,952 | 3,543 | 9,000 | 3,120 | 74.5 | 505* |

| VacoVent 2 x 7.5 kW | 826 550 | 15 | 1,260 x 1,300 x 2,500 | 7,952 | 3,780 | 10,000 | 3,100 | 74.5 | 524* |

| ventilator S 400/G/S6R | 874 601 | 11 | 1,605 x 1,535 x 1,960 | 7,952 | 3,770 | 10,000 | 3,150 | 74.5 | 210 |

| ventilator S 400 G/S6R | 874 611 | 15 | 1,605 x 1,535 x 1,960 | 7,952 | 4,050 | 10,000 | 3,840 | 74.5 | 230 |

Filter unit

| type | art. no. | filtration surface area | details | dimensions L x W x H (mm) | weight kg |

|---|---|---|---|---|---|

| N-1800 16/65 | 633 160 | 65 m² | incl. pressure surge cleaning, control, filter pressure box and indicator light | 1,970 x 1,970 x 2,490 | 860 |

| N-1800 20/81 | 633 170 | 81 m² | incl. pressure surge cleaning, control, filter pressure box and indicator light | 1,970 x 1,970 x 2,890 | 940 |

Discharging unit

| filter substructure | art. no. | dimensions LxWxH (mm) | total height for attachment N-1800 16/65 incl. discharging substructure (mm) | total height for attachment N-1800 20/81 incl. discharging substructure (mm) |

|---|---|---|---|---|

| chip container with agitator and discharge screw with 1.1 kW for the connection to a briquetting press | 635 510 | 1,650 x 1,580 x 1,000 | 3,490 | 3,890 |

| chip container with discharge screw with 0.37 kW for the connection to a screw conveyor | 635 510 | 1,650 x 1,580 x 1,000 | 3,490 | 3,890 |

| chip container with 2 chip collection containers (8-cornered) | 635 355 | 1,600 x 1,750 x 1,400 | 3,890 | 4,290 |

| chip container with discharge screw motor drive and agitator with 0,37 kW prepared for (ATEX-rotary valve ZRS 10 430) | 635 650 | 1,780 x 1,525 x 1,300 | 3,790 | 4,190 |

| chip container prepared for (ATEX-rotary valve ZRS 10 1400) | 635 340 | 1,650 x 1,580 x 1,400 | 3,890 | 4,290 |

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.