For lowered energy costs

- Efficient recovery of thermal energy

- With it the new fresh air is preheated

- Reduction in heating costs because a heating system usually can be sized smaller

- Break-even in just two to three years (depending on climate conditions)

Questions

on this product?

Description

Recycling plays a critical role in today’s economy. This is not only good for the environment, but also easy on the carpenter’s pocketbook.

Why not recycle heat?

Due to the presence of solvents called volatile organic compounds (VOCs) in the exhaust air from spray booths and systems, conveying the exhaust back into the spray booth or into the workshop is not permitted. This normally means that the supplied heat is lost. With its air-to-air heat exchanger, Schuko has succeeded in recycling the heat from the exhaust air. It provides a simple way to save money with ‘nothing’.

A heat exchanger in your company will be worthwhile because in terms of overall costs it pays off in every respect.

The principle is very simple:

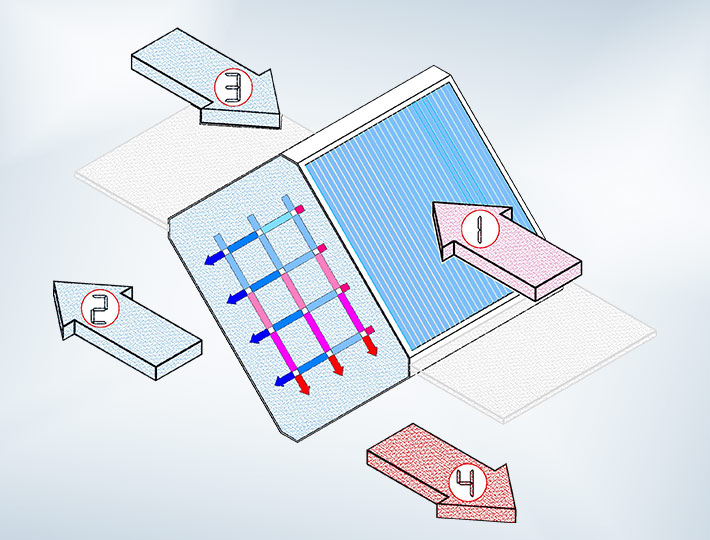

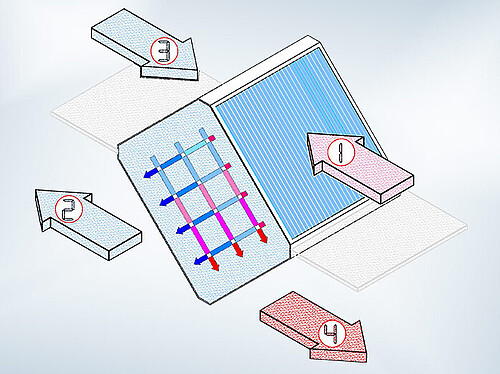

The hot exhaust air, e.g., from a spray booth is conveyed through a connected duct system to the heat exchanger. Inside, part of this heat is removed from the exhaust air and stored in aluminium fins. At the same time the cold fresh air flows through the heat exchanger on the other side of the aluminium fins.

The thermal energy is transferred and returned to the spray booth. The downstream heating register which heats up the make-up air thus receives preheated air.

Schuko uses two types of heat exchangers:

1. crossflow heat exchanger

2. rotary heat exchanger.

Crossflow heat exchanger

As described above, the supplied hot exhaust air is conveyed through the heat exchanger. However, this air takes a criss-cross path, as can be seen in the drawing. The fin spacing is 9 mm for this heat exchanger.

This large spacing has the following advantages:

- Lower resistance

- Less contamination

- Sustained efficiency

- Easier cleaning

Other advantages of the crossflow heat exchanger:

- No mechanical parts ⇒ low-maintenance

- Easy cleaning due to removable aluminium blocks

- No cross-contamination between airstreams (leakage air)

- Low space requirements

- Low flow resistance

- Easy retrofitting

The efficiency of the crossflow heat exchanger is 45% to 65%. The slightly lower efficiency compared with that of the rotary heat exchanger is compensated for by the above advantages up to a certain system size.

This type of heat exchanger has been shown to be ideal for small and medium-sized enterprises and contributes to maximising energy savings for low to medium air volumes with little effort.

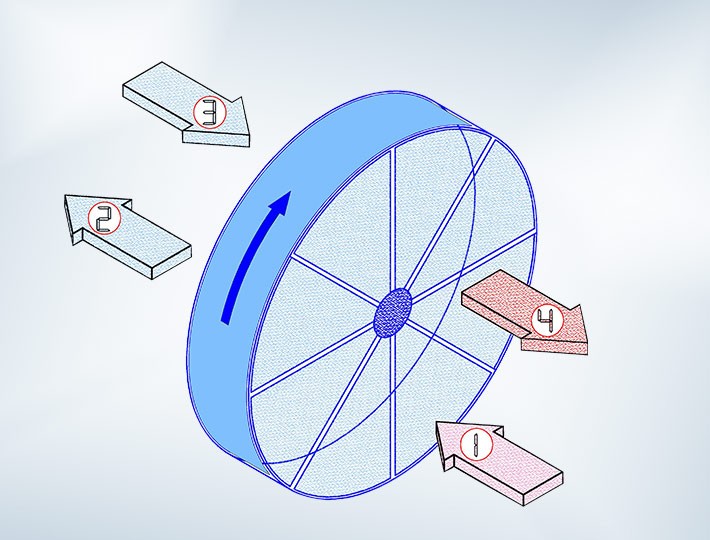

Rotary heat exchanger

A honeycomb-structured rotor rotates continuously between the make-up and exhaust airstreams. The rotor is heated by the exhaust air and transfers the heat to the cold fresh make-up air which is then supplied to the operations.

Advantages of the rotary heat exchanger:

- High efficiency of up to 80%

- Suitable for high to very high airflows

- Automated cleaning available

- Low space requirements

This heat exchanger is usually used in operations with very high airflows because the higher investment costs and ongoing costs (drive and cleaning) for large systems are balanced out by the higher efficiency.

![[Translate to Englisch:] Rotations-Wärmetauscher](/fileadmin/_processed_/e/d/csm_Rotations-Waermetauscher-Prinzip_8a022ce353.jpg)

Contact an expert in advance to clarify which size and version are right for your operations. Our advisors are available at all times to assist you.

Downloads

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.