Mobile dust extractor with three chip collection tanks

- Space-saving dust extractor for single- or multi-point extraction

- H3 test mark (wood dust), dust class M

- Equipped with externally loaded filter bags

- Optionally left or right mounted suction nozzle

- Delivered preassembled and ready to plug in for immediate use

Questions

on this product?

Description

The Vacomat 200 XPe mobile dust extractor is the ideal filtration system for single- or multi-machine extraction. Reliable airflows of up to 2,495 m³/h are possible with this negative pressure system, making it ideal for, e.g., dust extraction from panel saws and small bandsaws.

In the standard version extraction is started manually with the push of a button. Automatic fan start-up upon switch-on of the connected machine tools can be installed upon request to avoid operating errors such as not switching the extraction on when there is a load or switching it on when there is no load.

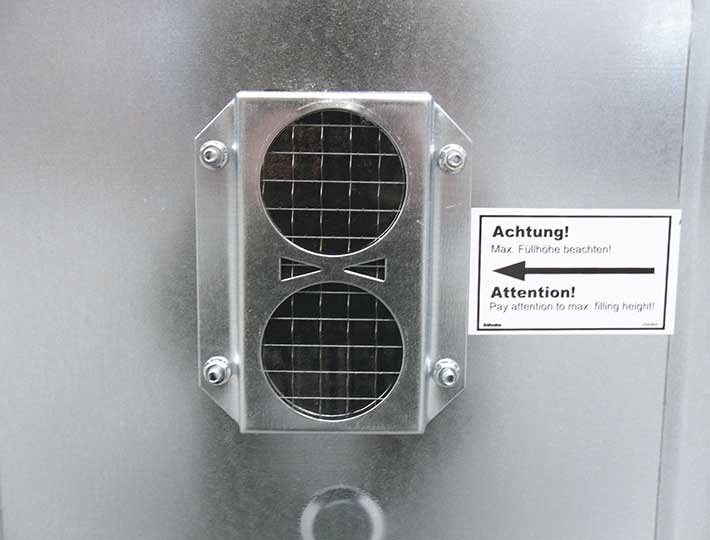

Dust and chips are discharged to three dust-tight plastic sack-lined chip collection tanks (3 x 160 l). A negative pressure duct holds the film sack in place in the collection tank. Inspection windows are provided for level checking.

The mobile dust extractor monitors the extraction performance via a load cell to ensure maximum operational reliability.

Filter regeneration

In the Vacomat 200 XPe an integrated switchgear cabinet is used for electromechanical cleaning via a shaker motor. Activation occurs via querying of the woodworking machine via floating contacts. As soon as all connected machines are off the motorised filter shaker starts automatically. For the regeneration mechanism no connection to a compressed air supply and thus no compressor is necessary. This leads to a significant reduction in noise during cleaning.

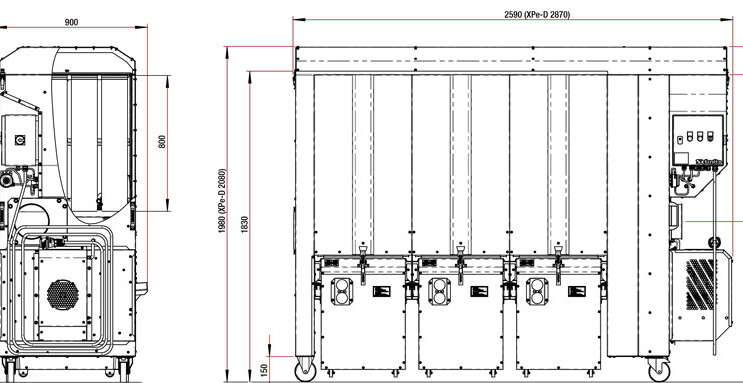

Recommended particularly for very high and very fine dust contents, an efficient pressure surge cleaning system(XPe-D) is optionally available (NOTE: overall height then +100 mm and length +280 mm). Cleaning is carried out offline via the compressed air tank after extraction.

Schuko filter bags

Schuko relies on externally charged filter bags

The separation efficiency of a mobile deduster does not depend solely on the filter material. Decisive is also its arrangement or execution. In principle, two types of filter bags are distinguished: internally or externally loaded filter media.

The major disadvantage of the inner filter bags lies in their shape: The dust mixture must be inside the filter bag to be separated from the air. With the inner curve, they provide the perfect template for material deposits - the suction power decreases. To make matters worse, the limited possibility of cleaning these filter bags added.

Precisely for these reasons, Schuko relies exclusively on the principle of externally loaded filter bags. The dust mixture only reaches the outside of the filter bag, so it can be cleaned much better. This means less resistance and more suction while maintaining a longer filter material life. Schuko filter fabrics are made of high-quality, antistatic polyester needle felt and are manufactured in Germany. Schuko's patented support basket made of filter-friendly plastic as well as the wear-free attachment of the filter bag have proven their worth over the past decades.

Installation & items delivered

Vacomat 200 XPe mobile dust extractors are delivered preassembled and ready to plug in (high-voltage current 16 A, with 6 m cable) on single-use pallets (included). A set of chip bags (3 pcs, size V) is also included.

The Vacomat 200 XPe must be electronically connected to the machine tools to enable automatic triggering of filter bag regeneration when the machine tools are shut off. An electronics company can help. The supplied switchgear cabinet with integrated phase inverter is prepared for querying of a floating contact as well as three transducer coils (coils are not included).

The dust extractor is directly connected to the machines for extraction (connection nozzle size of 200 mm) with a flexible hose or rigid ductwork. Some of the connection parts can be found in the accessories section as well as our system components section.

Equipped with stable industrial-grade casters, the mobile dust extractor can be set up flexibly anywhere in your workshop. Need extraction for a different machine? Just release the brakes on the two casters and push the unit to the required location.

We would be happy to assist you in the planning!

Technical Data

| Vacomat | 200 XPe |

|---|---|

| Art. no. | 304644 |

| Suction nozzle Ø (mm) | 200 |

| Motor (kW) | 4.0 |

| Maximum flow rate (m³/h) | 2,495 |

| Nominal volume flow at 20 m/s (m³/h) | 2,262 |

| Suction pressure pa | 2,800 |

| Filter surface area (m²) | 14.5 |

| Weight (kg) | 465 |

| Sound pressure level (dB[A]) | 75 |

| Chip collection volume capacity (l) | 3 x 160 l |

| Measurements L x W x H (mm) | 2,590 x 900 x 1,980 |

Downloads

Product brochure

mobile dedusters Vacomat brochureMobile dust extractors with chip collector for indoor installation are suction units ready to be connected for the extraction of one or more machines.3 MB

mobile dedusters Vacomat brochureMobile dust extractors with chip collector for indoor installation are suction units ready to be connected for the extraction of one or more machines.3 MB

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.