Dry paint mist extraction for wall installation

- For collection of liquid organic coating materials

- High separation efficiency due to three-stage filtration of paint mist

- Space-saving construction with large filter surface area

- Low installation depth for tight spaces

- With Schuko effect for improved extraction

- Multiple extensions available for increasing extraction surface area

Questions

on this product?

Description

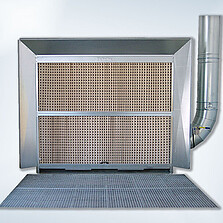

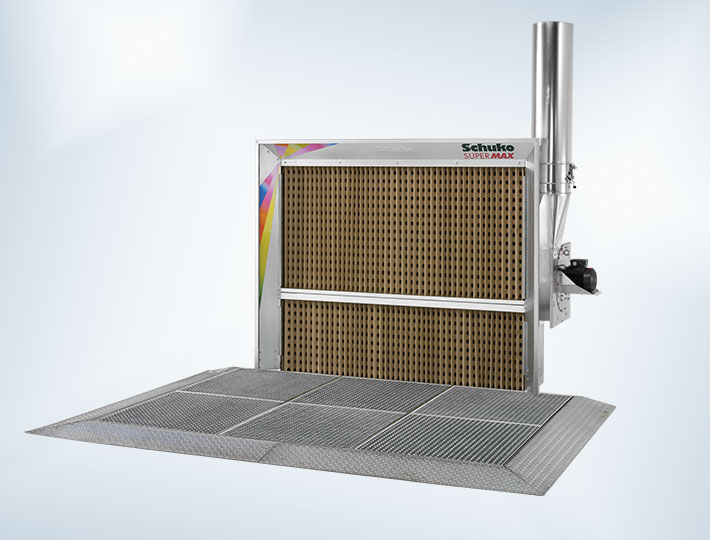

The SuperMax paint mist extraction wall provides for optimal air quality during spraying. Workpieces are positioned in front of the extraction wall and sprayed in the direction of the extraction surface.

All SuperMax paint mist extraction systems are equipped with the Schuko effect. The suction power is greatly improved through introduction of turbulence into the paint mist. Overspray is thus collected directly by the extraction system and trapped in the first filter stage by the front cardboard filter mat. Here the paint particles enter the retention pockets, where they accumulate and cure. This is followed by a non-woven fibreglass filter and a fine filter through which the remaining solids are filtered out. The clean air is discharged to the outside of the building by an exhaust system. This occurs via exhaust air ducts leading through the wall or ceiling.

Extraction results in a negative pressure in the spray booth because air is removed. Adequate supply of fresh air must be ensured. Air make-up units represent a suitable solution. We would be happy to include a heat exchanger in the planning to enable use of the heat from the exhaust air to heat the new fresh air for lowered heating costs.

With the low installation depth of just 800 mm this spray wall can be space-savingly installed on the wall. Due to the ease of access changing of the economical filter mats is fast and unproblematic. Additionally available drip pans with bevelled edges keep the workshop floor clean.

The inexpensive spray wall is manufactured as a compact construction, satisfies the high Schuko quality standard and meets all safety requirements for spraying tasks.

Other advantages

- Inexpensive paint mist extraction system with full functionality

- Effective extraction with large filter surface area

- Three-stage filtration of airstream for a clean and healthy environment

- High-quality VHC cardboard filter mats with 50% more retention capacity

- All spray equipment requirements met to ensure high operational reliability

- Adjustable flash-off operation via air control damper

- Easy access for fast and simple filter change

- Delivered ready to plug in for immediate use

Installation & items delivered

For transport reasons the SuperMax is delivered in disassembled condition on a Euro pallet. It can be assembled quickly with the help of the supplied easy-to-follow assembly instructions. The connection socket must be permanently installed outside the hazardous area.

Items delivered:

- Components for SuperMax paint mist extraction wall (including assembly materials)

- Extractor fan, explosion-proof in accordance with VDMA 24 189 Part 1, motor PTB-tested

- Large front filter mat (upper deflector surface) made from VHC cardboard filter (flame-retardant)

- Small front filter mat (lower deflector surface) made from VHC cardboard filter (flame-retardant)

- Inner filter cage with non-woven fibreglass filter and particulate matter filter mat F5

- Connection cable of length 7.0 m with a CEE Nolta motor protection plug which is also the on/off switch (the socket must be situated outside the hazardous area!)

Technical Data

| Type | SuperMax I | SuperMax II |

|---|---|---|

| Art. no. | 519 700 | 519 780 |

| Motor U/Min. | 2,905 | 2,915 |

|

Power kW (400 V / 50 Hz) | 2.2 | 3.3 |

| Protection level | EExe, II, PTB No. Ex-86/3447 | dto. |

| Nominal volume</br>flow m³/h | 5,500 | 6,400 |

| Deflector surface</br>area m² | 3.2 | 3.2 |

| Exhaust pipe Ø mm | 350 | 350 |

|

Measurements L x W x H mm | 2,700 x 800 x 1,840 | 2,750 x 800 x 1,840 |

|

Dimensions including extension L x W x H mm | 3,020 x 1,080 x 2,120 | 3,080 x 1,080 x 2,120 |

| Weight kg | 195 | 203 |

The following products might also interest you:

Questions on a particular product?

Call our product advisor on 0049 7581 4871 0 or use the form below. A Schuko employee will only visit you if you explicitly require it and have indicated this above.

![[Translate to Englisch:] technische Zeichnung Farbnebel-Absaugwand SuperMax [Translate to Englisch:] technische Zeichnung Farbnebel-Absaugwand SuperMax](/fileadmin/_processed_/b/6/csm_Zeichnung-Farbnebel-Absaugwand-Supermax_789e69bd6c.jpg)

![[Translate to Englisch:] technische Zeichnung Farbnebel-Absaugwand SuperMax mit Ansaugflächen-Erweiterung [Translate to Englisch:] technische Zeichnung Farbnebel-Absaugwand SuperMax mit Ansaugflächen-Erweiterung](/fileadmin/_processed_/2/5/csm_Zeichnung-Farbnebel-Absaugwand-Supermax-mit-Ansaugflaechen-Erweiterung_7bb7abdbb0.jpg)